Note: This post is a work-in-progress and will be updated as requirements are fully fleshed out.

See CATPOO 2021 — A New Beginning for an overview of the whole project.

It’s about time I ruminate on power issues I’ve had in the past. In previous iterations, I cut a lot of corners with the power. Melted wires and malfunctioning steppers were the main issues I remembered facing. This brain dump will be help to avoid all the power issues in this next, final holonomic robot.

Past Power Problems

- Previous designs considered power supply as an afterthought

- Running all stepper motors off a single power supply proved problematic

- The amount of current passing through would often surpass what the power supply was capable of

- Microstepping would fail or become unreliable due to voltage irregularities

- Even regular steps would cause problems

- If I needed 1A max for a load, then I’d only have 1A max available

- Designing power circuitry like I worked for Apple was a bad idea, as all that does is lead to overheating

- Sometimes wires would melt or components would release the magic smoke from within

What’s Worked in the Past

- Using a beefy SPDT switch to allow powering the robot externally or from battery proved helpful

- Keeping the external and internal power physically separated avoided a lot of potential issues

- It was very simple to troubleshoot power input issues as things were very simple

- The battery should be easy to access and replace

- At minimum, it should be easy to recharge.

- Physically replacing it easily is a nice to have, especially when I show up with multiple fully-charged batteries

Strategies and Mitigation Plans for the Future

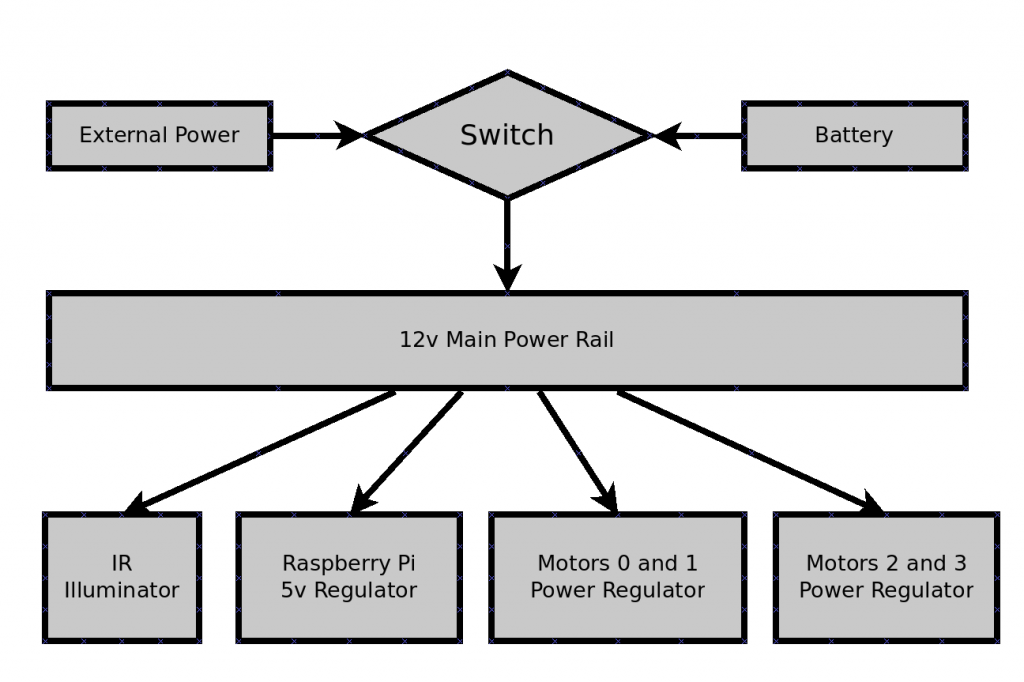

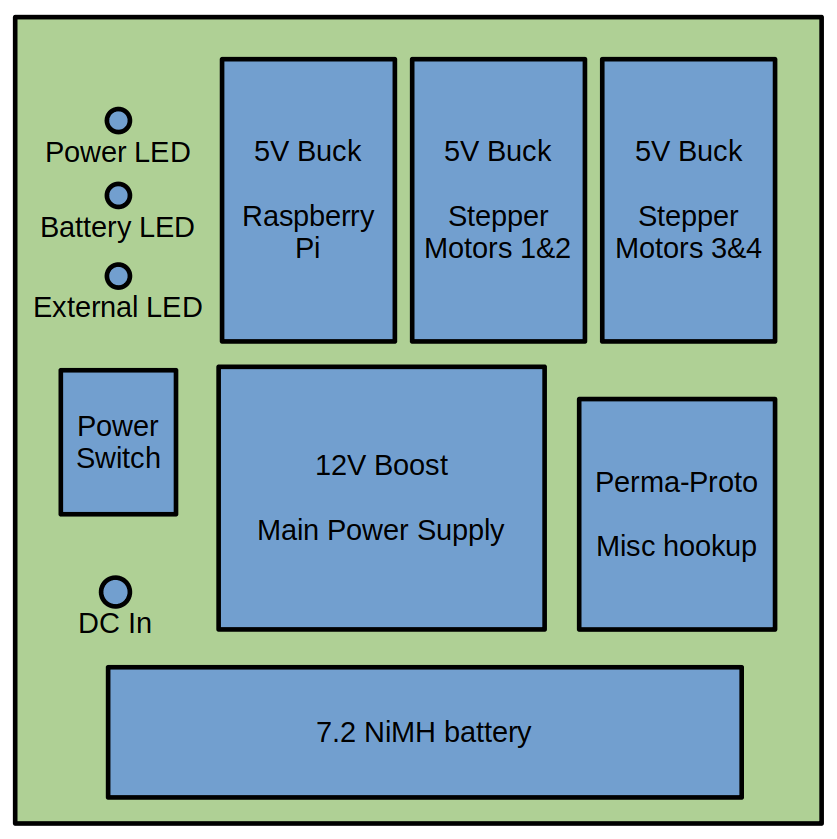

- Have one single 12v main power rail that everything else connects to

- There exist high powered buck boost voltage regulators that have more than enough

- Going overkill on the main rail will leave me with more power than I know what to do with

- I don’t want to have to remove functionality again due to lack of current

- This will allow me to scale the robot up to whatever size I would like

- From the main 12v rail, I’ll use a series of buck converters to get the proper voltage(s) required

- Build and be prepared to handle lots of current (12V * 5A = 60W)

- Once I get good, I can drop the power requirements.

- Until then, assume the following padded numbers:

- 5V × 5A for Raspberry Pi and peripherals

- 4 motors * 2 coils/motor * (2.7V * 1A) for the motors

- 5V * 1A padding for feature creep

- Total power at worst: (5V*5A) + 4 * (2*2.7V*1A) + (5V * 1A) = 52W

- My best guess of average power would be more like 35W

- On battery power, it’s looking like I’ll be discharging around 1 to 2C maximum. I can’t find power ratings for the batteries that I have, but it’s looking like a lot of comparable ones are 25C, 50C or even higher.

- This beefy adjustable voltage regulator should work and looks like it tops out at 120W. The description says it’s good at 8A with passive cooling. That should give me around 96W.

- Dedicated power regulator for Raspberry Pi and peripherals

- I want to shoot for 5V @ 5A, because I don’t want to be pushing anywhere near the limits

- Raspberry Pi 3-4 maxes out between 2.5A and 3A

- There will be a 5″ touch screen that draws 400ma max (RPi max peripheral current draw is 1.2A)

- Dedicated power regulators for pairs of motors

- There will likely be 4 steppers with omni wheels attached.

- Ideally, I’d want a separate power supply for each stepper motor and driver combo, but two per regulator should be good enough.

- It’s definitely better than before

- Have the front left motor and the back right motor on one power rail, and the front right and back left on another

- Theory: hopefully this will cause power fluctuations to balance out

- Have the IR illuminator draw right off the main 12v rail

- I’d like to add a way to enable or disable this, to reduce power usage when it’s not necessary

- It’s also nice for comparing IR versus no-IR

- A physical switch seems like the obvious MVP, yet I’d like the ability to turn it off via software

- I’d like to add a way to enable or disable this, to reduce power usage when it’s not necessary

Notes

- Having an LED on all power rails

- I want to be able to diagnose common issues from across the room

Diagrams and Illustrations

Tim-Doerzbacher.com

Tim-Doerzbacher.com